Ultrakustik Floor Plast

Ultrakustik Floor Plast sound-insulating leveling coating is applied in soundproof floor structures of a floating type as a leveling elastic layer below the screed over uneven monolithic, prefabricated, or combined structural floorings. Request PriceInnovative Sound-insulating Leveling Coating

Ultrakustik Floor Plast is a pelletized polymerizable material made from expanded polystyrene which acts as an elastic sound-insulating layer in “floating” type floor structures.

Levels Unevenness of Floorings

Pelletized mixture eliminates local overflows, cracks, and cavities on the flooring surface , covers fine particles of construction waste as well as reinforcement protrusions and burrs.

Engineering Utility Lines may be Located Inside the Ultrakustik Floor Plast Layer

Ultrakustik Floor Plast can be used in premises with a large number of engineering utility lines.

Electric wiring, heating system pipes, water supply lines, and other utilities may be placed inside the Ultrakustik Floor Plast layer.

Quick Installation without Preliminary Floor Leveling

Ultrakustik Floor Plast pelletized mix may be easily, quickly, and uniformly applied on the floor surface with the use of a conventional float trowel.

The material does not need any pre-cutting and excludes waste and cut-offs.

Features

Ultrakustik Floor Plast plays the role of an elastic sound-absorbing layer in the soundproofing "floating floor" design. Before applying the Ultrakustik Floor Plast sound-insulating leveling compound, make sure that the local unevenness of the floor and the size of construction debris do not exceed 10 mm (0.4 in). Before installation of screed, it is necessary to wait for complete polymerization of the 20-mm (0.8 in) thick mix for 48 hours at a temperature no lower than 15°С (5 °F). A leveling screed with a thickness of at least 60 mm (2.4 in) is laid directly on the Ultrakustik Floor Plastcoating and must necessarily be reinforced with metal structures for increased mechanical strength.

Video content for Ultrakustik Floor Plast

Maintenance info

Composition and description of Ultrakustik Floor Plast

Ultrakustik Floor Plast sound-insulating leveling coating is a ready-for-use mixture of an elastic vibration insulation material.

It is made of polystyrene foam pellets, Indian rubber, and acrylic binder developed using an innovative formula.

- Ultrakustik Floor Plast is not a matrix for development of bacteria, mold, and other harmful microorganisms ensuring safety and durability

- Ultrakustik Floor Plast practically does not adsorb moisture and does not require any additional waterproofing

Storage and Transportation

Ultrakustik Floor Plast can be transported by any means of transport. Transportation at subzero temperatures is allowed, provided that there are no more than three cycles of freezing-thawing.

A package of the Ultrakustik Floor Plast pelletized mixture should be stored in warm, dry enclosed premises in a packed form.

When in storage, Ultrakustik Floor Plast boxes should be placed on wooden pallets, boards, or other padding materials to avoid sagging.

Features of the material usage

Ultrakustik Floor Plast sound-insulating leveling coating is a ready-to-use pelletized mix of elastic vibration insulating material which, after being applied on the flooring surface, performs the function of soundproofing lining under the leveling screed in the “floating floor” structures.

Before installation of a coating with a standard thickness of 20 mm (0.8 in), all debris with a fraction size of more than 10 mm (0.4 in) shall be removed from the flooring surface.

The 15-30 mm (0.6 – 1.1 in) thick coating is applied directly onto the flooring manually or mechanically.

The material is compacted to the required thickness using a polyurethane float trowel. The time of complete polymerization for a 20-mm (0.8 in) thick layer is 48 hours at a temperature no lower than 15°C (5 °F).

Ready-to-use constructions with Ultrakustik Floor Plast

See allPhysical Properties

Physical and Technical Properties

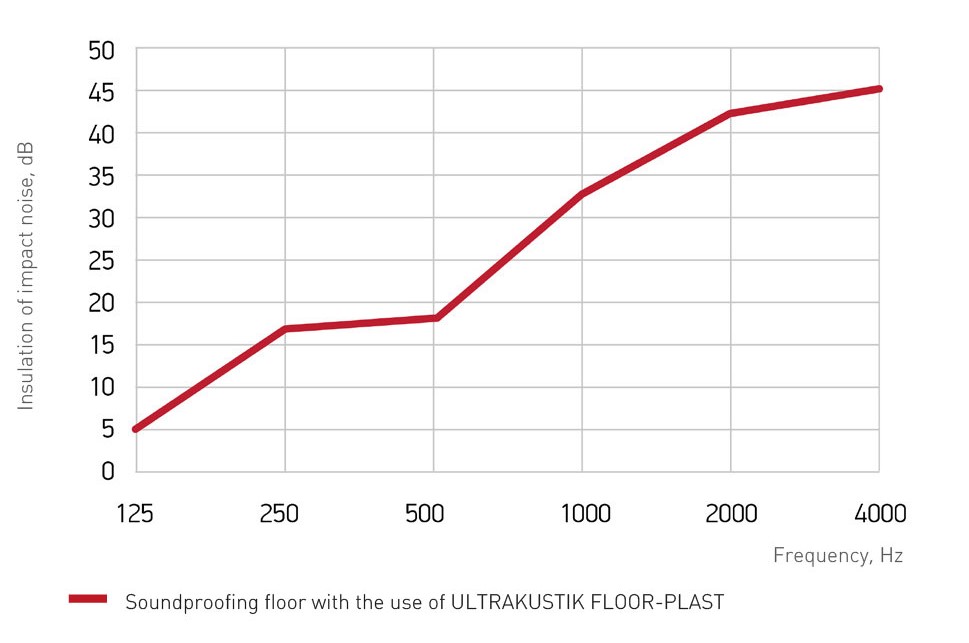

Additional Shock Noise Insulation: 31 dB

Reduction of the reduced shock noise level with a floating screed with 100-120 kg/m2 (20.4 – 24.5 lb/ft3) surface, placed on top of 10-20 (0.4 – 0.8 in) thick Ultakustik Floor Plast coating.

Additional Air-borne Sound Insulation: 9 dB

Downloads

Product Information

Technical information

Didn't find what you were looking for? Just ask us!

Popular questions

First of all, there is different rigidity of the finished floor structure - conventional foam plastic is harder than Ultrakustik Floor Plast. In this case, extra rigidity negatively influences the normalized shock noise index.

Ask your question

If you couldn't find an answer to your question on this page, don't worry. Ask us and we will respond as soon as possible. We usually answer questions during the working day. You can also leave a review about the material. Your opinion is very important to us!Questions/reviews from site visitors

Engineering utility lines should be covered with a heap 10 mm (0.4 in) thick.

Maximum thickness of Ultrakustik Floor Plast coating is 50 mm (2 in).

Ultrakustik Floor Plast can level local floor unevenness not exceeding 10 mm (0.4 in).